Liquid Oxygen Plant

We are a leading company for manufacturing and exporting premium quality liquid oxygen plants in technical collaboration with an internationally acknowledged company ING. L. & A. Boschi of ITALY. Our company has gained recognition in the engineering sector for bringing the much talked Low Pressure Technology for designing and manufacturing of liquid oxygen plants. The ISO 9001:2000 certified company is also recognized in the industry as a manufacturer and exporter of technologically advanced liquid oxygen plants. In order to deliver reliable and durable plants, we incorporate the raw materials taken from CE approved vendors.

Basic Principle

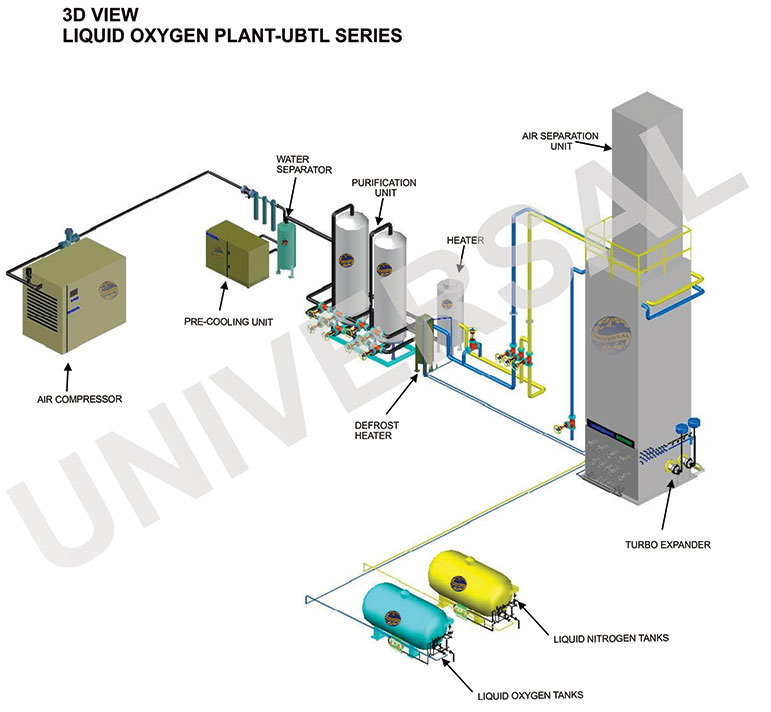

We are supplying low pressure plants manufactured by us with the following main components:

- Low pressure Rotary compressor, Atlas copco air compressor or Oil free piston air compressors.

- Low pressure driers.

- Low pressure refrigerant drier.

- Turbo expander.

- Low pressure air separation unit.

Salient Features of the Plants

The demand of our liquid oxygen plant is increasing each day. The increment is seen due to a number of salient features, including:

- Low power consumption

- Low upkeep expense

- Sturdy design & compact design

- User–friendly

- Easy operation

- Fully automatic

Production Process

Air is sucked by a multi stage air compressor and air passes through the following process:

| Step 1 | Compression of Air This is accomplished by the multistage highly advanced air compressor. |

| Step 2 | Purification of Air This is fulfilled by the Process Skid. |

| Step 3 | Cooling & Liquification of Air This is finished by a highly advanced expansion engine and also by a refrigeration unit (for 100% liquid output). |

| Step 4 | Air Separation (Rectification) This is done by the special 'BOSCHI' type AIR SEPARATION UNIT comprising of upper & lower column and special exchangers. The separation of air is accomplished by the CRYOGENIC PROCESS. The final product from a liquid Oxygen/Nitrogen goes to the storage tank. |

| Technical Specification | |||||||

| Production | UBTL-50 | UBTL-100 | UBTL-200 | UBTL-300 | UBTL-400 | UBTL-500 | UBTL-1000 |

|---|---|---|---|---|---|---|---|

| Liquid Oxygen output(liters per hour) | 60 | 120 | 235 | 350 | 470 | 590 | 1172 |

| Purity Oxygen (%) | 99.7 | 99.7 | 99.7 | 99.7 | 99.7 | 99.7 | 99.7 |

| Liquid nitrogen output(liters per hour) | 73 | 144 | 290 | 435 | 578 | 700 | 1440 |

| Purity nitrogen (%) | 99% to 99.999%or ppm | 99% to 99.999%or ppm | 99% to 99.999%or ppm | 99% to 99.999%or ppm | 99% to 99.999%or ppm | 99% to 99.999%or ppm | 99% to 99.999%or ppm |

Whatsapp

Whatsapp