Liquid Nitrogen Plant

We are leading manufacturer of liquid nitrogen plants that are designed and developed using high quality technology. Our liquid nitrogen plant generates liquid nitrogen with high purity up to 99.99%. For ensuring high quality machinery, we use the latest cutting Italian technology. Constructed with the best materials, our plants are reliable, durable and cost-effective. Since we place high premium on quality, we have got a dedicated team of engineers and technicians who oversee the plants from commissioning to installation at the client's site.

We have got a large manufacturing unit in New Delhi, India. All machinery and spare parts of the plants are manufactured at our factory. We have a team of qualified engineers who manufacture air separation columns using high quality stainless steel. We offer liquid tanks filling plants with production capacities ranging from 20 Liters/hr to 1000 Liters/hr. We have been awarded ISO 9001:2008 and CE certifications.

Important Features of 99.99% Pure Liquid Nitrogen Production Plant and Machinery

- Air separation column (Cold Box) is made of A Grade leakproof stainless steel.

- It can be used with a Skid Mounted version.

- It is quick to start and easy to maintain.

- Trouble free operation for long time.

- Spare parts easily available.

- It consumes very low power.

Product Description

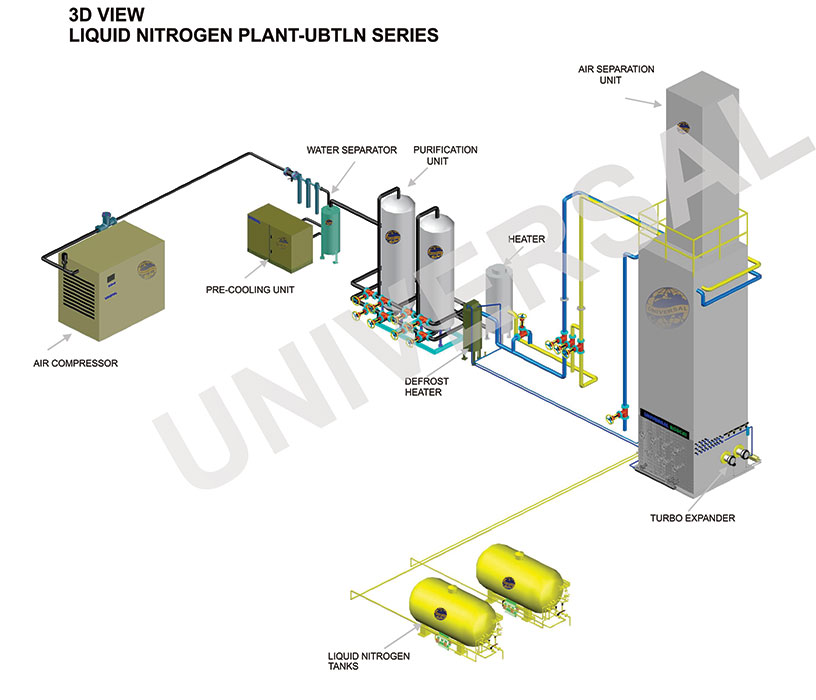

Compression of Atmospheric Air by Air Compressor : Air is compressed at a very low pressure of 5-7 bar (kg/cm2). Air can be compressed at such low pressure by advanced rotary compressor (screw/centrifugal type advanced technology is employed in place of old bulky piston compressor).

Pre Cooling System : The second stage of the process uses a low pressure refrigerant for pre cooling the processed air to temperature around 12 deg c before it reaches the purifier.

Purification of Air by Purifier : The air goes inside a purifier comprising of twin molecular sieve driers, working alternatively. The molecular sieves alleviate the carbon dioxide & moisture from the processed air before the air enters air separation unit.

Cooling of Air by Turbo (Expander) : The air has to be cooled to sub zero temperatures for liquification & the cryogenic refrigeration & the cooling is offered by highly efficient turbo expander, which cools the air to temperature almost below -165 to-170 deg c.

Separation of Liquid Air into Oxygen and Nitrogen by Air Separation Column : Oil free, moisture free and carbon dioxide free air enters into low pressure fin type heat exchanger where the air is cooled below sub zero temperatures by air expansion process in the turbo expander. Air gets liquefied when it enters the air separation column & gets separated into oxygen & nitrogen by the process of rectification. Oxygen is available at the outlet of the asu at a purity of 99.7%. Nitrogen is also available t the outlet as a second product at purity of 99.9% upto 3ppm simultaneously without loss of oxygen product.

Compression of Oxygen and Filling of Oxygen in Cylinders : The final product in the form compressed oxygen/nitrogen goes to the high pressure oxygen cylinders at 150 bar or upto higher as required.

Applications of Liquid Nitrogen

- OIL & GAS

- BEVERAGE & FOOD INDUSTRY (COCA COLA , JUICE BOTTLING )

- FREEZING SEAFOOD & other items

- NITROGEN REFINERY

- TUNNEL FREEZING

- In the veterinary industry for the cryopreservation of blood cells like (sperm and egg)

- GLASS INDUSTRY

- Used for food preparation, in order to make ultra-smooth ice cream

- & Many Others

| Technical Specifications | |||||||||||

| MODEL | PRODUCTION IN M3/HR | PRODUCTION LITERS/HOUR | PURITY | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| UBTLN-50 | 50 | 73 | 99.99 To 99.99999% | ||||||||

| UBTLN-100 | 100 | 145 | 99.99 To 99.99999% | ||||||||

| UBTLN-200 | 200 | 218 | 99.99 To 99.99999% | ||||||||

| UBTLN-300 | 300 | 435 | 99.99 To 99.99999% | ||||||||

| UBTLN-400 | 400 | 578 | 99.99 To 99.99999% | ||||||||

| UBTLN-500 | 500 | 724 | 99.99 To 99.99999% | ||||||||

| UBTLN-1000 | 1000 | 1440 | 99.99 To 99.99999% | ||||||||

| UBTLN-1500 | 1500 | 2171 | 99.99 To 99.99999% | ||||||||

| UBTLN-2000 | 2000 | 2894 | 99.99 To 99.99999% | ||||||||

| UBTLN-3000 | 3000 | 4341 | 99.99 To 99.99999% | ||||||||

| UBTLN-4000 | 4000 | 5788 | 99.99 To 99.99999% | ||||||||

| UBTLN-5000 | 5000 | 7235 | 99.99 To 99.99999% | ||||||||

Whatsapp

Whatsapp